- Homepage

- Smart Manufacturing

Smart Manufacturing

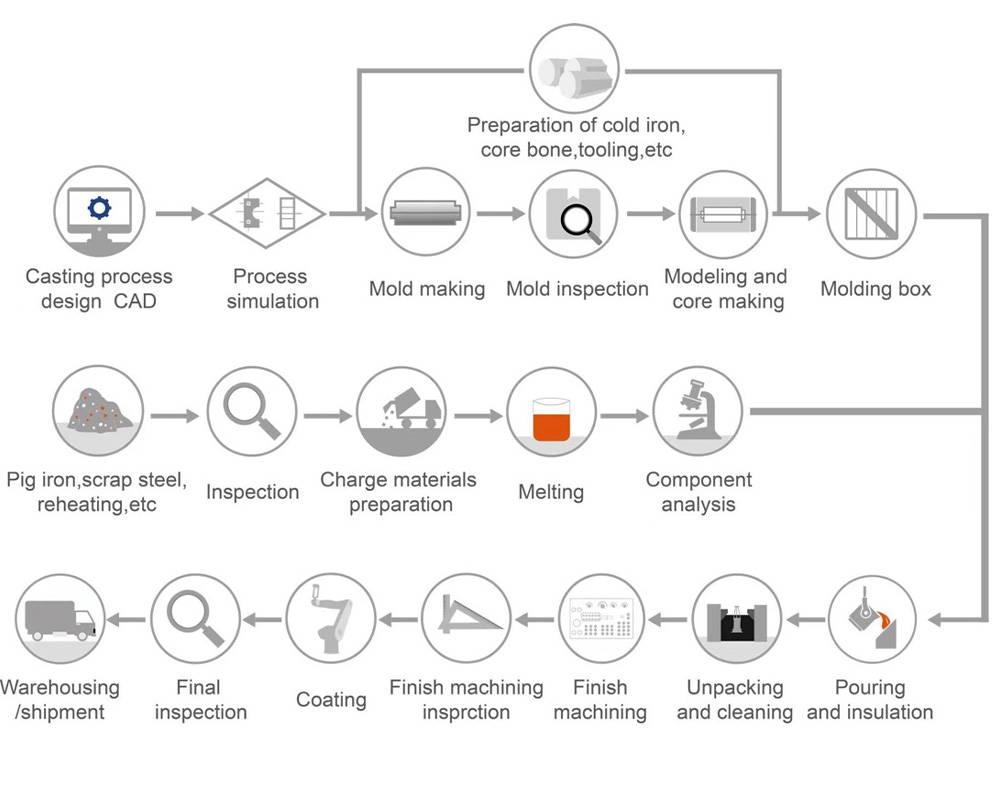

Casting

High-Quality, Environmentally Friendly Castings

Premium configuration, sustainable production, and cutting-edge technology.

- Cast Steel

- Cast Iron

Integrating Advanced Technology, Building the Production Lines of Tomorrow.

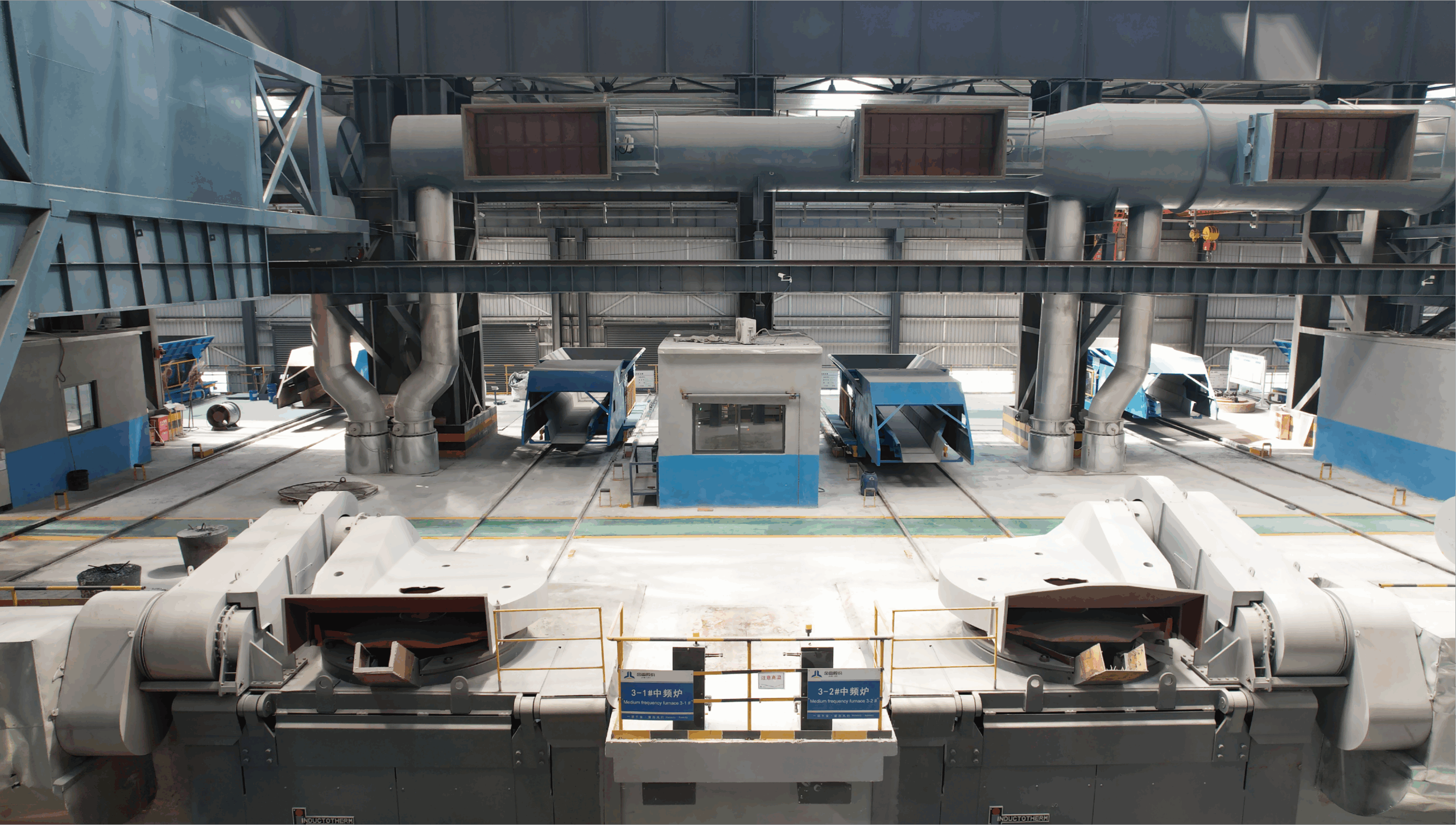

Our workshop is equipped with state-of-the-art facilities and has established in-depth cooperation with the Institute of Metal Research, Chinese Academy of Sciences. Adopting the design philosophy of “technology solidified into equipment, equipment integrated into production lines,” we combine advanced domestic technologies like purified smelting, full airtight protection casting, and ultra-high temperature demoulding with optimized equipment selection and plant design. This integration ensures the mass production of high-purity, low-segregation, and micro-defect large-scale fan main shaft castings, with an annual production capacity of 200,000 tons of forgings, achieving high quality, efficiency, and stability.

Technology Integration for High-Quality Production

Our workshop is fully equipped with advanced facilities and has established strong collaboration with the Institute of Metal Research, Chinese Academy of Sciences. Guided by the principle of “technology solidified into equipment, and equipment integrated into production lines,” we combine leading domestic technologies such as purified smelting, airtight protection casting, enhanced insulation, and ultra-high temperature demoulding. These innovations, integrated with optimized equipment selection, workshop layout, and plant design, enable the large-scale production of high-purity, low-segregation, and micro-defect fan main shaft castings. Our operations deliver high-quality, efficient, stable, and safe mass production, with an annual forging capacity of 200,000 tons.

Comprehensive finite element simulation of forging with a complete

and integrated process workflow.

- Smelting

- Casting

- Forging

- Heat Treatment

- Machining

- Coating

Technology Embedded in Equipment, Equipment Integrated into Production Lines

This integration enables the high-purity, low-segregation, and micro-defect-free mass production of large wind turbine main shaft cast billets with attributes of high quality, high efficiency, stability, and operational safety. The facility boasts an annual production capacity of 200,000 tons of forging billets.

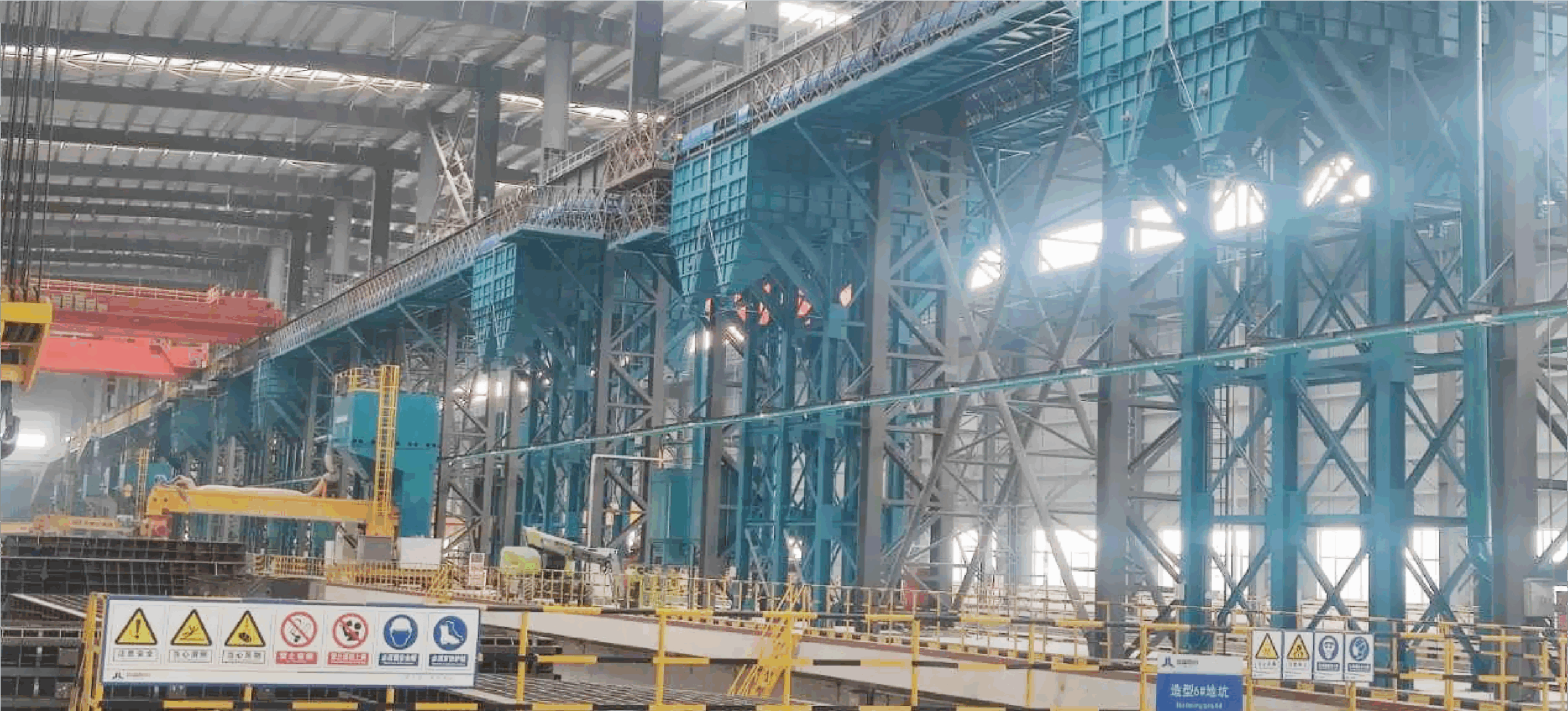

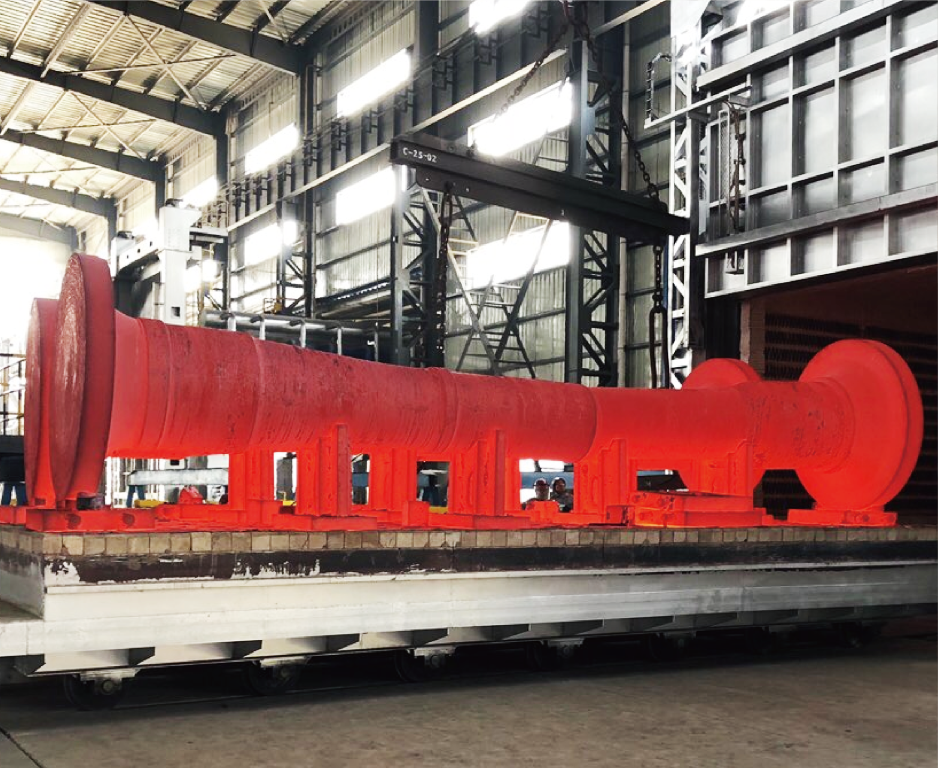

High-Standard, High-Specification, Environmentally Friendly, and Premium Castings

By introducing top-tier industry technology, management systems, and experienced technical teams, and adopting advanced, proven production processes in combination with steel refining equipment and techniques, the company produces high-performance, dense, and clean-surface premium castings that meet the demanding requirements of offshore and large-capacity wind power applications.

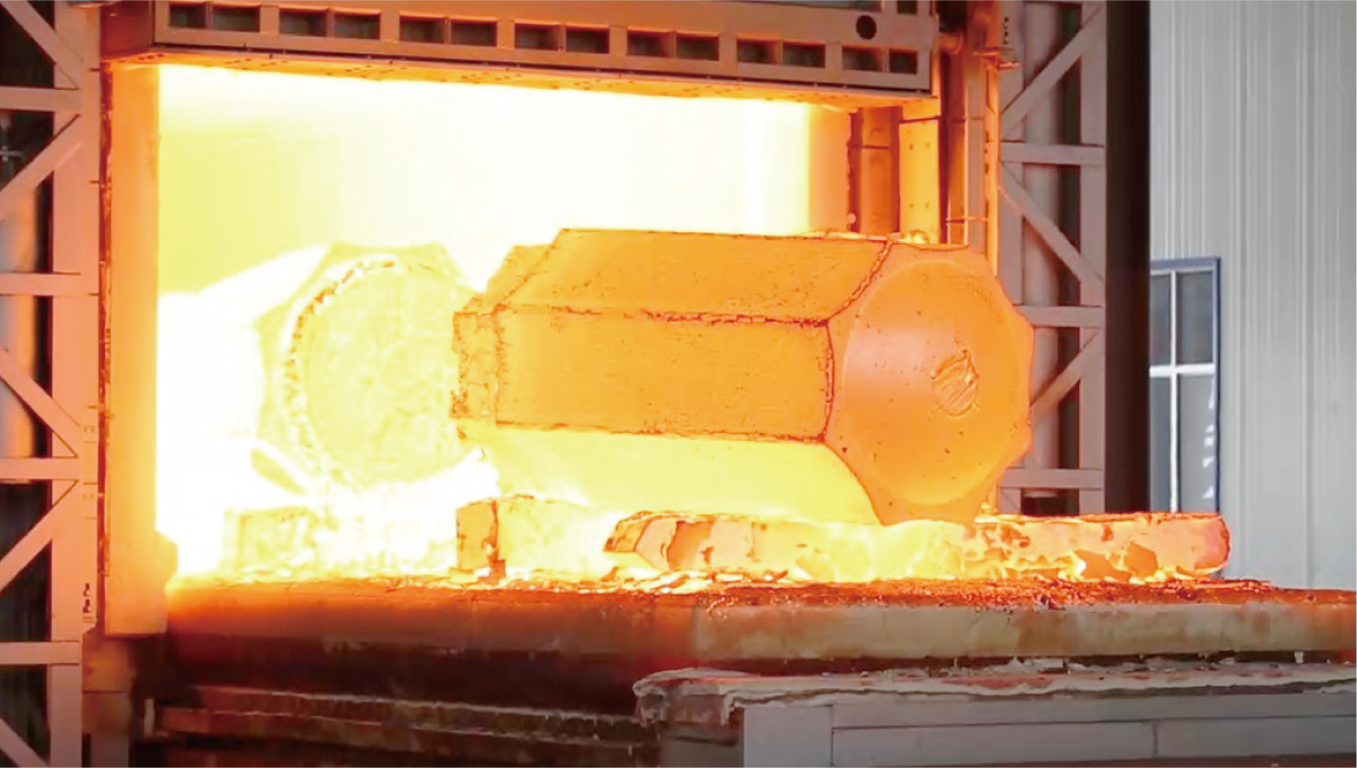

Finite Element Forging Simulation with a Complete Process Workflow

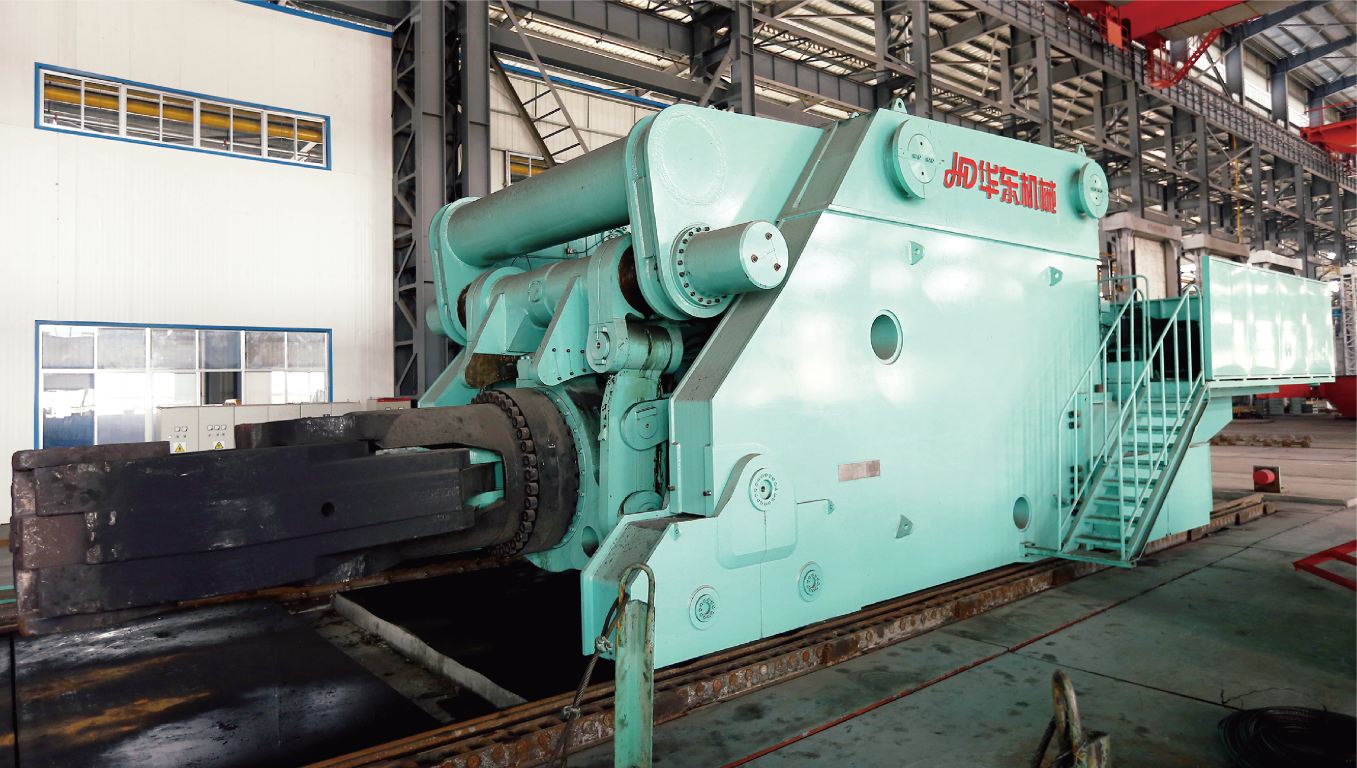

Its hollow main shaft forging technology is among the most advanced globally. The workshop is equipped with industry-leading equipment, including a 10,000-ton forging press, a 150-ton fully hydraulic manipulator, fully automated regenerative heating furnaces, and heat treatment furnaces. The production capacity and equipment configuration rank at the forefront of the industry, with an even larger 15,000-ton press slated for commissioning soon.

State-of-the-Art Equipment and Advanced Processes

Through collaboration with leading universities such as Shandong University and Shanghai Jiao Tong University, the workshop adopts advanced quenching and tempering processes, utilising precise temperature control systems and imported quenching media to achieve uniform temperature distribution and deep, consistent hardened layers.

The combination of cutting-edge equipment and high-precision program control provides a strong guarantee for the high performance and reliability of the company’s products.

Streamlined Processes and Standardized Procedures

The workshop has implemented workflow standardization and process procedure optimization, effectively maximizing the productivity and advantages of its advanced machining equipment. This provides a solid and reliable foundation to meet customer requirements and adapt to evolving market competition.

Streamlined Production and Automated Operations

In line with the “Made in China 2025” strategic initiative and its commitment to developing smart factory capabilities, the construction of these coating lines was jointly designed with internationally renowned robotics manufacturers to achieve automated operations. This initiative has positioned the company at a leading level within both the domestic and global wind power industries.

Our company has fully mastered core technologies across the entire production chain for high-quality steel components, from ingot preparation and forging to heat treatment, machining, and coating. We employ cutting-edge purification smelting technology and fully airtight protective casing to ensure material purity, complemented by intensive riser insulation and ultra-high-temperature demolding techniques that enable precision forming of large-scale components.

A particular area of excellence is our fiber-reinforced hollow forging technology for wind turbine main shafts, recognized as industry-leading. This is supported by advanced finite element simulation technology and specialized heat treatment processes that guarantee homogeneity in massive forgings. Our digital quenching system for hollow spindles represents another technological breakthrough, ensuring optimal material properties. In machining operations, we utilize specialized CNC systems featuring polar coordinate processing tailored for wind turbine main shafts, along with hydrodynamic deep rolling technology that enhances surface integrity and fatigue resistance. Our fully automated intelligent coating systems complete the value chain with consistent, high-performance surface protection.

Through strategic collaborations with leading Chinese universities and research institutions, we maintain access to emerging technologies in wind energy component manufacturing. This cooperative ecosystem ensures our processes incorporate the latest advancements in the field. For wind power ductile iron castings, we implement customized composition design technology supported by real-time composition monitoring with precision control. Our proprietary metal mold casting technique, combined with electric arc furnace and LF furnace refining processes, produces castings that consistently meet the demanding "Triple-High" standards of high performance, high internal density, and high surface cleanliness - critical requirements for reliable wind energy operation.

-

-

Molding Workshop

-

Liquid Iron Activity Technology

-

Liquid Iron Purification Technology

-

Metal Mold Casting Technology

-

-

Precision Casting Workshop

-

Electric arc furnace and LF furnace refining technology

-

Ingredient Customization Technology

-

Precise ingredient detection and control technology

-

-

-

-

Heat Treatment

-

Homogenization Heat Treatment Technology for Large Forgings

-

Digital Quenching Technology for Hollow Spindles

-

-

Rough and fine processing

-

CNC machining technology

-

-

Finishing workshop

-

Polar coordinate CNC machining technology for wind turbine main shaft

-

Wind turbine main shaft hydrostatic deep rolling technology

-

-

Coating

-

Fully automatic intelligent coating technology

-

-

-

-

Precision casting workshop

-

Purification smelting technology

-

Fully airtight protection casting technology

-

Riser strengthening and insulation technology

-

Ultra-high temperature demoulding technology

-

-

Forging

-

Hollow forging technology of all-fiber wind turbine main shaft

-

-

Technology Department

-

Finite element simulation technology

-

-